Case Study Infineon: GORE® Protective Membrane for Cutting-Edge Gas Sensors

Case Studies, United States

Partnering for Innovation: Gore and Infineon Take Gas Detection Sensors to a New Level

Learn how Gore technology added the final touch to fully unleash the potential of Infineon’s cutting-edge photoacoustic spectroscopy (PAS) for CO2 detection. Discover how joined efforts achieved a sensor response time nearly cut in half, paving the way for a new range of applications.

Challenge

In recent years, the heightened focus on health and well-being has emphasized the significance of indoor air quality. Infineon, one of the leading sensor solutions manufacturers, seized this opportunity to further elevate their innovative PAS sensors for CO2 detection. As the demand for high-quality gas sensors was – and still is – on the rise, they aimed for optimized performance and a streamlined manufacturing process.

Photoacoustic spectroscopy has been a known technology for gas detection for several years now. However, Infineon developed a state-of-the-art sensor standing out with a particularly compact design. To develop it to its fullest, Infineon turned to the industry leader, Gore, who has the same innovative mind-set and ambition. Fortunately, they found their perfect match in Gore.

Solution

Infineon's cutting-edge PAS sensors require minimal background noise in the absorption chamber for precise CO2 measurement. Thus, developing a suitable solution for our customer presented unique challenges.

Usually, Gore designs traditional vents to offer acoustic transparency. In this project, rather than minimizing the acoustic attenuation to ensure optimum sound experience, we were asked to design a membrane with maximum attenuation – while also allowing target gases to diffuse and achieve the shortest possible response time. Finally, the solution had to withstand high temperature requirements Infineon's defined packaging processes.

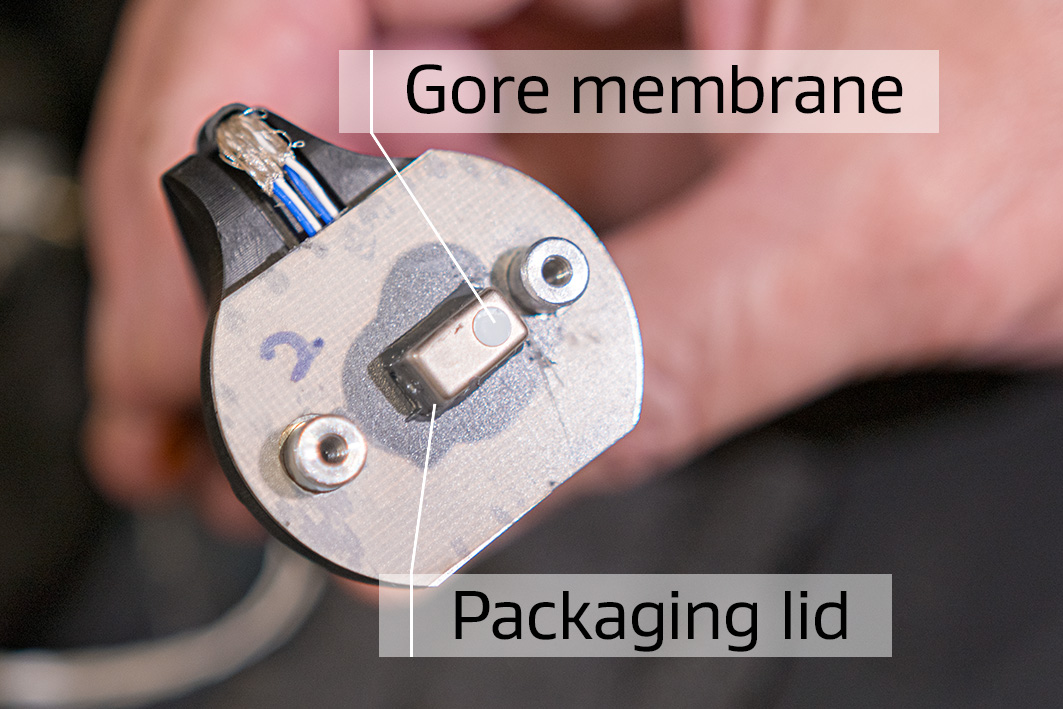

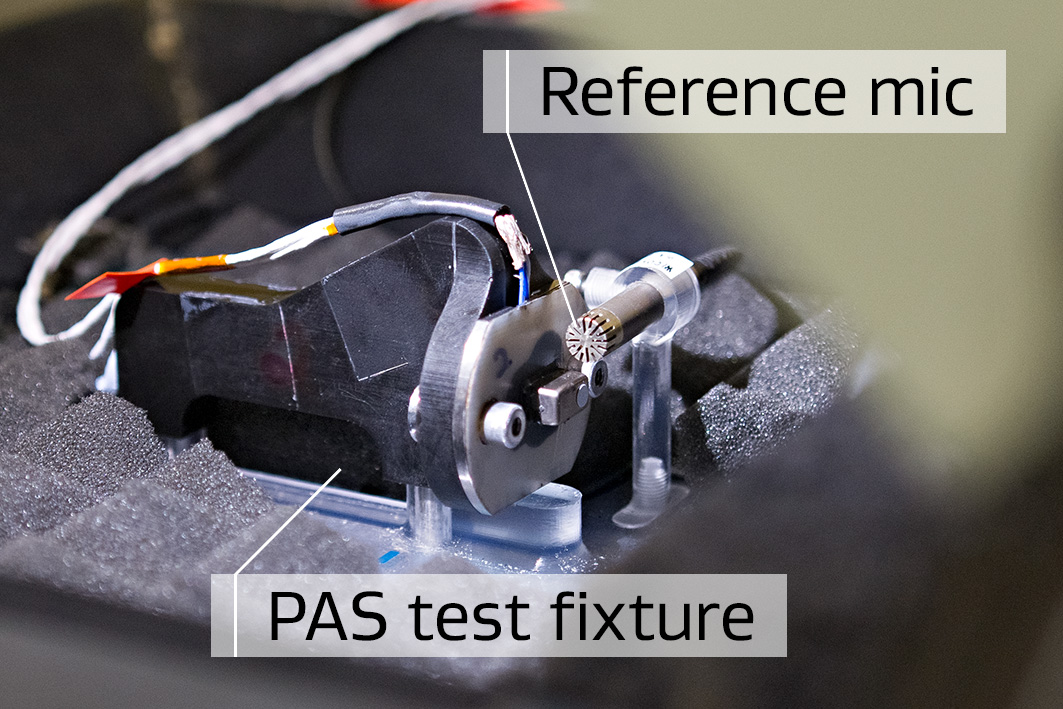

Driven by the pursuit of innovation, the engineering teams on both sides worked with unparalleled pace and motivation. To find the perfect fit for Infineon, Gore developed an acoustic test method to identify the right membrane options, leveraging Gore capabilities and industry knowledge. Those were then tested (see figures 1 and 2) while Infineon evaluated their final performance.

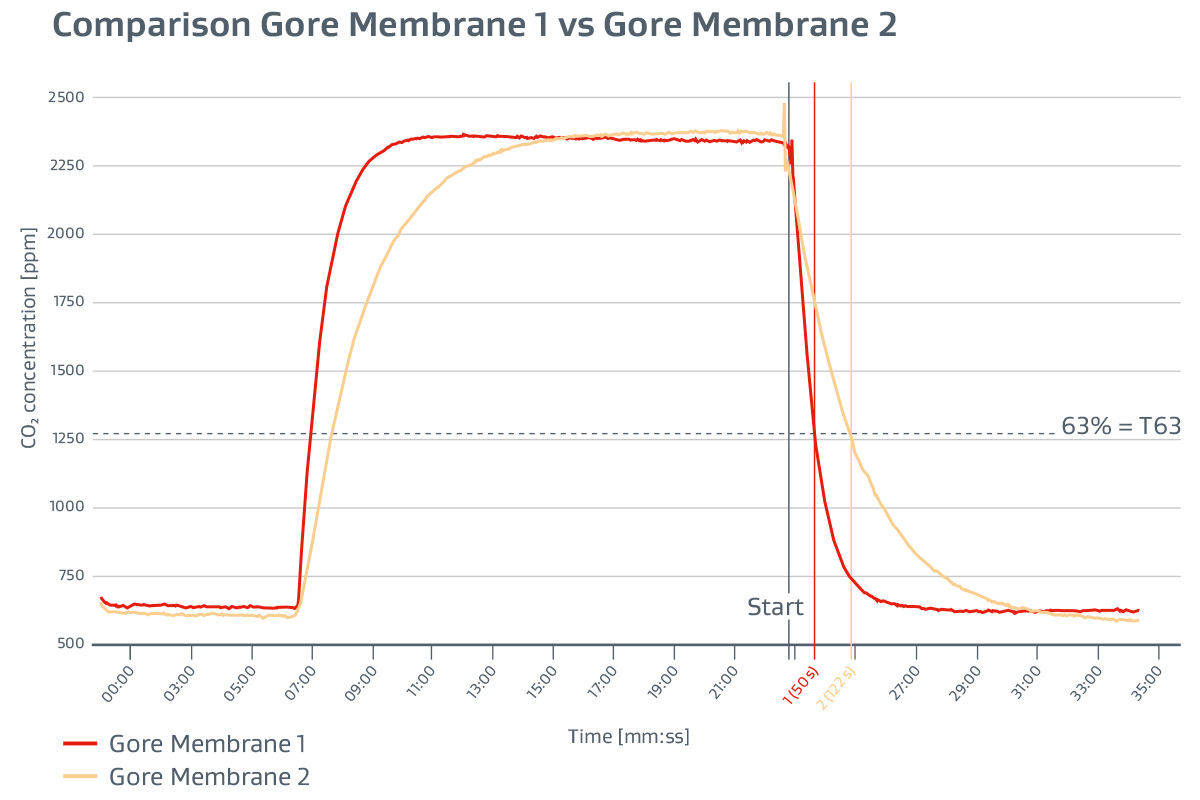

To conduct the response time test (see Figure 2), the Gore team placed the PAS sensor in a closed box and injected a specific amount of CO2 to reach a CO2 concentration of about 2300 ppm. Once a stable state was accomplished inside the box, our experts measured the response time T63 for the CO2 decrease until room conditions were reached again.

Figure 1a: PAS test fixture with an Infineon packaging lid and Gore membrane

Figure 1b: PAS test fixture installed in an anechoic box with reference microphone.

Figure 2: Investigation of two Gore membranes for the Infineon PAS sensor. The tests were conducted by placing the sensor in a sealed box and injecting CO2 until a stable concentration of 2300 ppm was reached. Then, the lid was opened and the response time T63 was measured for the CO2 decrease until room conditions were reached again.

This entire project phase stood out with transparent exchange and seamless communication between Gore and Infineon.

Ultimately, Gore’s combined expertise in acoustic performance, gas diffusion, and sensing applications led to a solution that does not only stand out with its performance, but also reduces the number of components inside the sensor to a single membrane.

Result

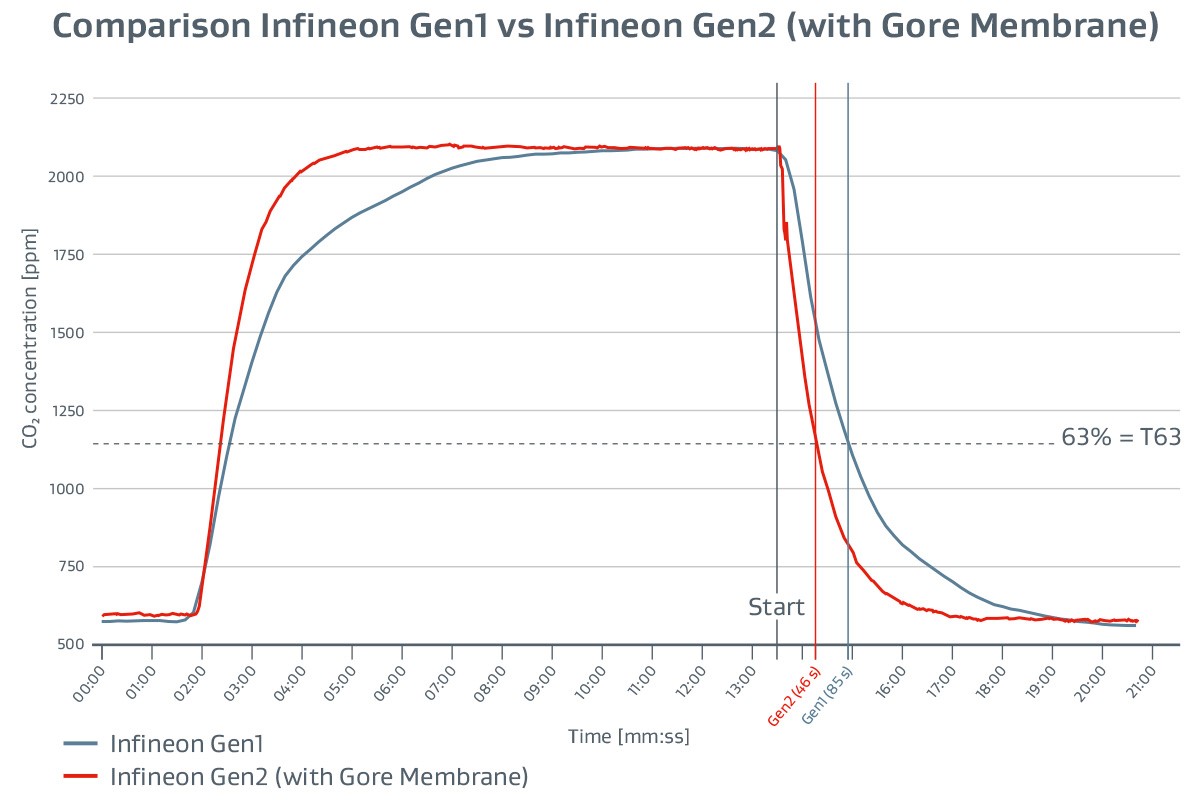

Excellent teamwork, transparent communication, and a shared innovative mindset between Infineon and Gore shaped the entire collaboration. This project marked the first time that Gore developed a membrane for photoacoustic sensing applications, surpassing all expectations with impressive results:

- Improved sensor response time by more than 40% compared to the first generation of Infineon’s PAS sensors while maintaining acoustic attenuation.

Figure 3: Response Time Curves of Gen1 (blue) vs Gen2 (red) leveraging a Gore membrane

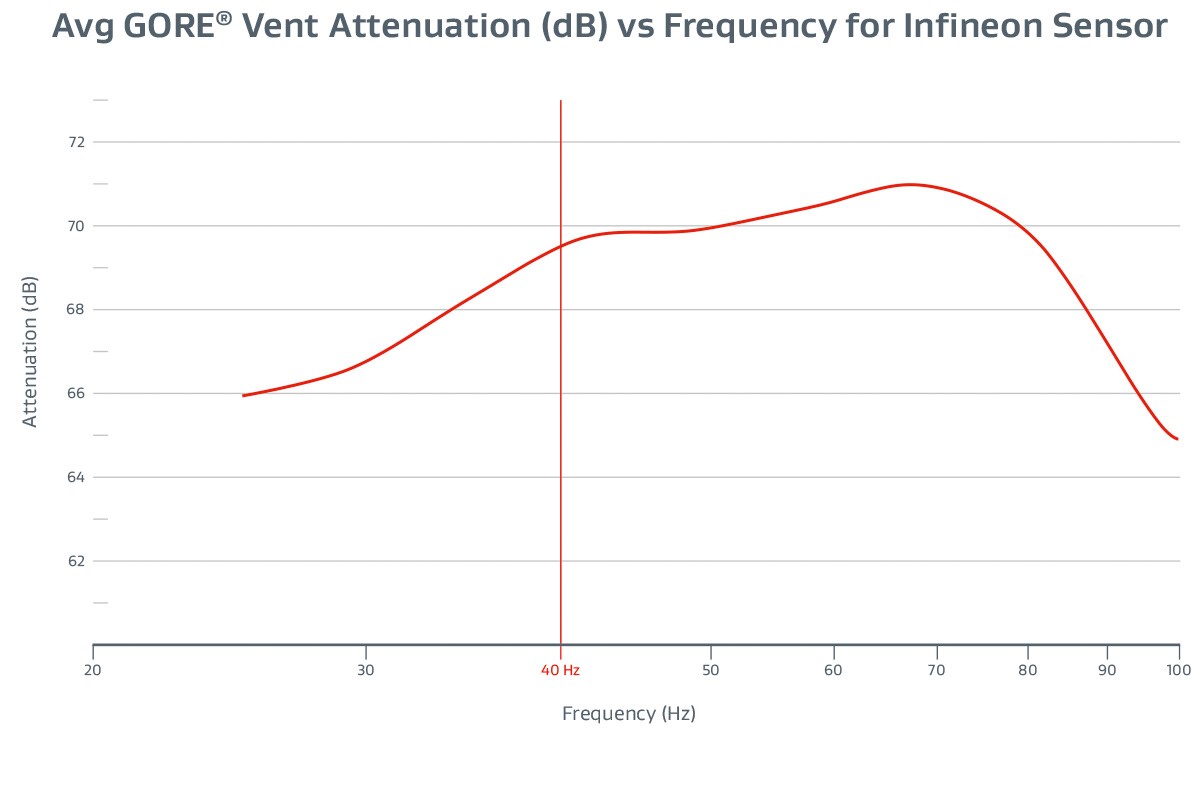

Figure 4 : Vent attenuation as function of frequency with special emphasis at 40Hz

- Replaced two components by a single high-performance membrane

- Simplified assembly process and enhanced cost efficiency

- Enabling further sensor applications through the new design, e.g. Smart Lighting, Agriculture, Smart Speakers & Conference Systems, In-Cabin Air Quality.

- Strengthened relationship between Gore and Infineon's global supply chain.

To get this story in a nice and easy to print or share format, please download the PDF by submitting the form below.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.