GORE® Automotive Vents for Li-Ion and EFB Batteries

GORE® Vents can enhance Li-Ion and lead-acid (EFB) battery performance and longevity, through effective pressure equalization and ingress protection.

Compact, Lightweight Protection for Enhanced Safety and Performance

GORE® PolyVents for easy snap-fit installation reliably protect EV battery packs and Battery Management Systems against pressure buildups while blocking ingress of damaging fluids and particles. For lead-acid applications, GORE® Catalytic Device effectively reduces electrolyte loss to improve the durability and lifetime of EFB Batteries.

GORE® Catalytic Device for lead-acid batteries

How our Catalytic Device capitalizes on Gore’s world-leading expertise in porous PTFE and catalytic membrane formation technology.

Technical Information

Gore monitors and strives to comply with all regulations applicable to our products.

We have worked with our suppliers to eliminate PFOA from our supply chain. Our products meet EU REACH regulations EU 1907/2006 and EU 2019/2021.

PPAP: An Overview

What Quality Means, to Us and for You

We commit to every customer that “our products will do what we say they will do" — and we stand behind that promise with our worldwide resources, expertise, and quality processes.

For Li-Ion Batteries and Battery Management Systems (BMS) for EVs

Product Name | Product Number | |

|---|---|---|

| PolyVent Standard | AVS 14 | AMF300114 |

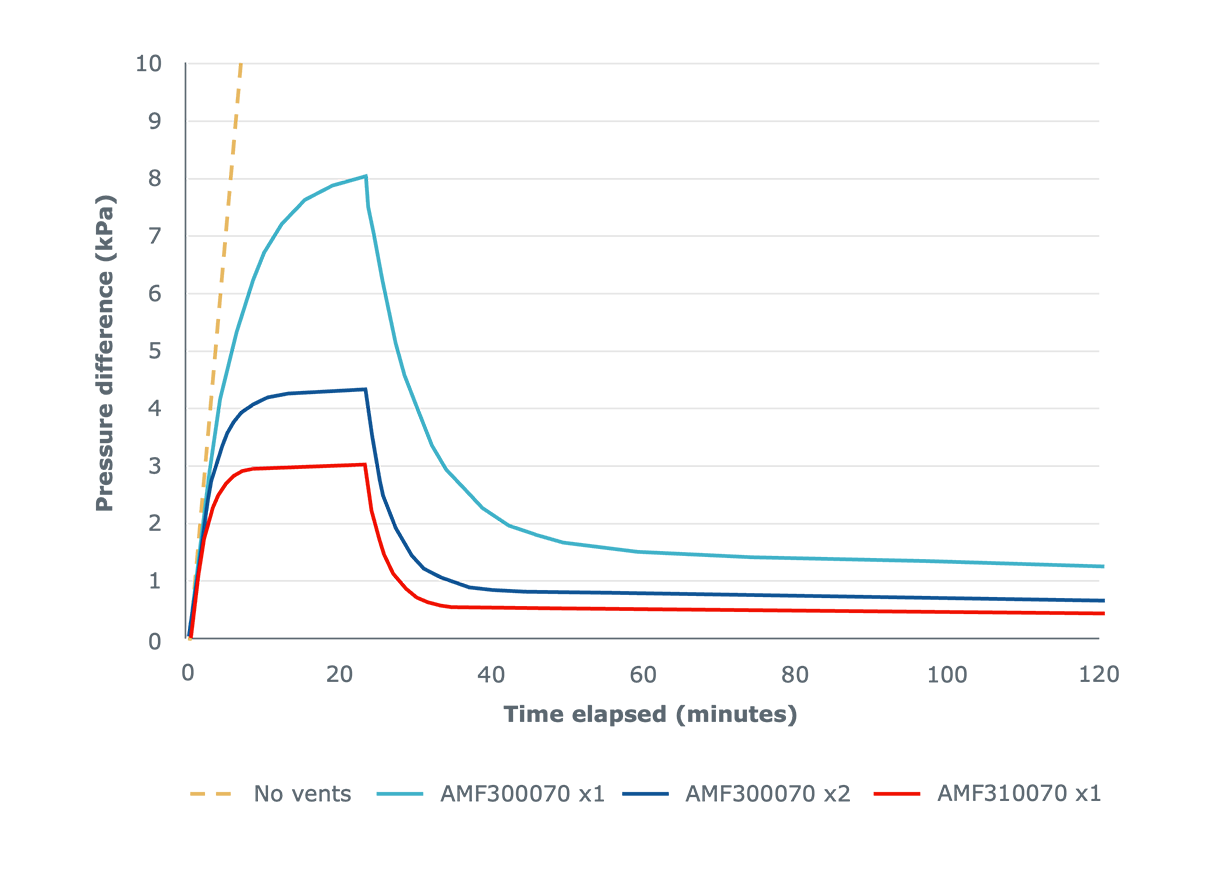

| PolyVent High Airflow | AVS 70 | AMF300070 |

| PolyVent Compact | AVS 200 | AMF300200 |

For Lead-Acid (EFB) Batteries

Product Name | Product Number | |

|---|---|---|

| GORE® Catalytic Device | SMPL-NVA9064 | NVA9064 |

Related Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 356 4622

Have questions or unique requirements?

Our experts are here to guide you.