Insulation, Camera, Action: Setting a new benchmark thanks to GORE® Thermal Insulation

Case Studies, United States

How to extend runtime without increasing size or lowering a device’s performance? We have an answer: Learn how GORE® Thermal Insulation added runtime to a 4K action camera while keeping its original size.

Challenge

A benchmark-setting client wanted to meet their customers’ demand for higher resolution, more performance and longer runtime of their action cameras while maintaining their compact size. The rapid advancements in camera technology – more powerful lenses, better chips, and AI feature implementation – generate more heat, thus reducing runtime, so the performance did not meet the customers’ expectation. With no option to enlarge the cases, our client asked us to provide a high-performance insulator as a solution to reduce heat while maintaining their status as one of the smallest 4K action cameras available. A challenging task, as this would mark the first time Gore Thermal Insulation (GTI) would be applied to cameras instead of mobile phones or laptops.

The client had previously contacted Gore, so when faced with this challenge, they relied on Gore’s reputation as an innovative material science company. And Gore did not disappoint.

Solution

In a fast-paced collaborative process with the client’s R&D-department, Gore developed a custom-made GORE® Thermal Insulation with the perfect balance of cost-awareness and efficiency. Several prototypes, were developed, tested, and optimized until the perfect match was defined and the runtime of the camera was increased by 90 seconds. For this task, Gore and the client took advantage of Gore’s own reliable supply chain and vast thermal insulation knowledge.

The Technology Behind the Solution: GORE® Thermal Insulation

GORE® Thermal Insulation combines less material with improved heat spreading, so heat is distributed more quickly and evenly, enhancing the components’ performance. This makes GORE® Thermal Insulation the perfect performance enhancer for small devices.

Here are some benefits of GORE® Thermal Insulation:

- High loading of aerogel to obtain low conductivity.

- Consistent distribution of aerogel to enable consistent conductivity.

- Consistent thickness.

For specifications and more detailed information, please visit GORE® Thermal Insulation.

Result

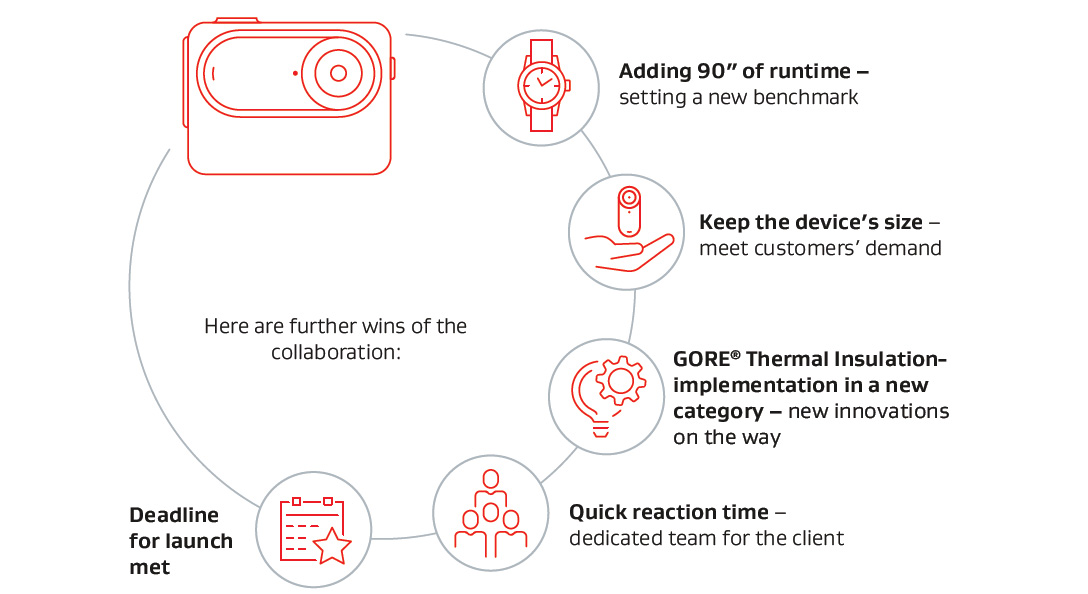

Focusing on their customers’ needs, Gore not only achieved the client’s primary goal of having a camera model running with 4K lenses without any compromise on device-size or runtime. We also met the client’s budget and timing requirements. The development process was characterized by rapid response times and a committed task-team proving both companies as market leaders and ahead of the competition.

Thanks to Gore’s own supply chain and dedicated team, the GORE® Thermal Insulation could be quickly adapted and mass-produced to meet the product launch deadline. Both companies look forward to future collaborations to set new benchmarks. These are further wins of the project:

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.