Defense Connectors for Aerospace & Defense Applications

Terminating connectors with cables and cable assemblies is critical and often where many stress points and interconnect failures can occur. Industry standards like SOSA™, MOSA and VITA often focus on just the electrical performance and gate-out of connectors without considering overall performance after cable termination. For example, a connector that operates reliably to 50 GHz with low VSWR and EMI suppression may only operate reliably to 18 GHz when terminated with a cable.

In reality, both the connector and cable must work well together to transmit high-quality signals and continuous data at desired frequencies and speeds to achieve success. So design engineers must select the appropriate connectors and cables and consider connector-cable interactions when designing or upgrading aerospace and defense systems.

That’s why at Gore, we believe testing connector-cable compatibility during the design phase ensures interconnects will perform as expected in specific applications for mission-critical success, survivability and safety.

Microwave/RF Connectors

We offer robust, low-profile aerospace connectors designed precisely for our flexible microwave cable assemblies. Connector variants include TNC, TNCA, SMP, SMPM, and SMA connector types, plus many more.

Our online Microwave/RF Cable Assembly Builder allows you to select connectors and then choose from specific cable types for optimal performance. If you know the parameters, you can choose the best cable type and select the right connectors that meet your specific system requirements.

Standard connectors mated with GORE-FLIGHT® Microwave Assemblies for defense aircraft.

GORE-FLIGHT® Microwave Assemblies offer TNCA, SMA, and Type N aircraft cable connectors in direct launch and field replacement variants with lock wire holes and self-locking features. Also available are size 8 BMA, BMB, and size 12 SMPM variants for use in MIL-DTL-38999 and ARINC 600 connector systems. Our assemblies provide a fit-and-forget solution delivering the lowest insertion loss, more reliable VSWR and superior EMI shielding after installation, in use and over time. They also operate reliably up to 40 GHz supporting mmWave Ka-band and V-band frequencies.

For defense land systems, GORE® Coaxial Cables are known to optimize 4K signals at 75 ohms and can be easily terminated with size 8 12G-SDI connectors.

Lastly, our standard space connectors include 2.92 mm, SMA, SSMA and SMP in various forms like straight pin or socket, 90° box pin or socket, 90° swept pin, 90° clip pin and many others. We also offer high-power connectors to reduce the risk of multipactor breakdown on SMA and TNC interface designs. In extreme power applications, our wedge TNC interface provides the lowest risk, multipactor-resistant solution.

When paired with GORE® Spaceflight Microwave/RF Assemblies, these aeronautic connector and cable combinations are proven to withstand the most challenging launch, orbit and deep space exploration environments. Each small, low-mass assembly paired with the proper aeronautical connector ensures uninterrupted signals in high-power, high-frequency, high-flex and high-density applications. Our products are also qualified for thermal extremes based on our long history of extensive testing and real-world applications.

High-Speed Connectors

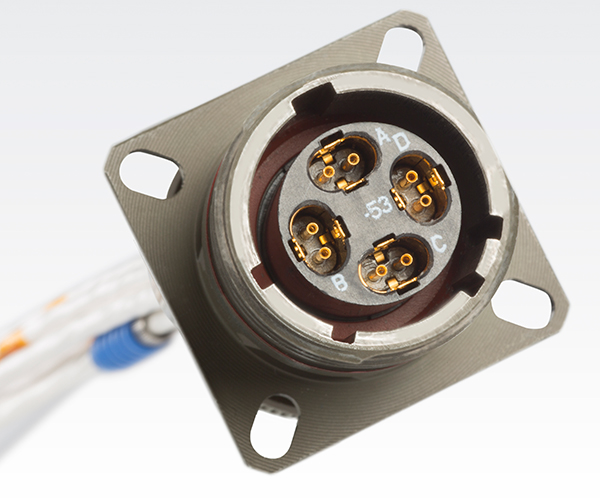

Gore offers high data rate copper and fiber optic cables in compact, durable and routable designs that fit standard military connectors and backshells. For instance, ARINC 600 and MIL-STD-38999 with size 8, 11 and 22D contacts, as well as size 8 differential Twinax and quadrax contacts.

Amphenol® OCS (Oval Contact System) terminated with GORE® Ethernet Cables, Cat6a version.

For standard Ethernet protocols, our engineers evaluated several designs of leading aerospace and defense connectors. The Amphenol® µ-Com and Glenair® El Ochito® connectors are examples that proved trustworthy in mechanical robustness and electrical performance when terminated with the Cat6a version of GORE® Ethernet Cables. Harting’s mil-spec rj45 connectors also performed reliably when terminated with our cables, plus many more.

We invite you to review the complete list of Ethernet connectors to help you choose the best option to terminate with our Cat6a version. You can also download termination instructions and related electrical data for connector-cable compatibility.

Available in Simplex and ribbon versions, GORE® Fiber Optic Cables can also be mated with MIL-PRF-29504 mil-spec connectors from COTSWORKS®, Radiall and other manufacturers.

For defense aircraft, the L3Harris™ FRCS (Field Replacement Connector System) with GORE® MIL-STD-1760 Assemblies is the only solution proven to guarantee safe operations with a low bend force in wide temperatures. This mil connector and cable have delivered 100% successful store releases on many platforms — unmatched by standard umbilicals using screw-on MIL-STD-38999/31 lanyard connectors.

Aerospace & Defense Industry Leader

Gore has provided microwave/RF cable assemblies to the aerospace industry since 1976. We offer award-winning solutions capable of operating reliably from DC to 110 GHz in the most demanding aircraft and spacecraft environments.

Since 1958, we’ve been a long-trusted partner to the aerospace and defense industry for wires, cables and sealants. Leading OEMs and suppliers rely on our proven, long-lasting solutions for mission-critical success, survivability and safety. We’re proud that our products have won industry awards and have been used in many applications — including every major aircraft, like the latest fifth-generation F-35 fighter jet.

Amphenol is a registered trademark of Amphenol Corporation.

COTSWORKS is a registered trademark of COTSWORKS, LLC.

Glenair and El Ochito are registered trademarks of Glenair, Inc.

L3Harris is a trademark of L3Harris Technologies, Inc.

SOSA is a trademark of The Open Group.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.