Definitions of Test Parameters

| Gb | The gasket stress at Tp = 1 when loading the gasket. It indicates the initial gasket stress required to seat the gasket with tightness. |

|---|---|

| "a" | The slope obtained by linear regression. It indicates the capacity of the gasket to ensure tightness. |

| Gs | The gasket stress at Tp = 1 when unloading the gasket. It indicates the capacity of the gasket to maintain tightness when pressure is applied, as well as the gasket's sensitivity to unloading. |

| Tp | The Tightness Parameter is dimensionless. A value of 1 corresponds to a Helium leak rate of 1 mg/s under atmospheric pressure for a gasket with an outside diameter of 150 mm. Note: the greater the Tp, the greater the gasket tightness. |

| Tpmax | The maximum tightness obtained when loading the gasket. |

| Tpmin | The minimum tightness obtained when unloading the gasket. |

- A gasket is placed in a hydraulic flat platen test rig.

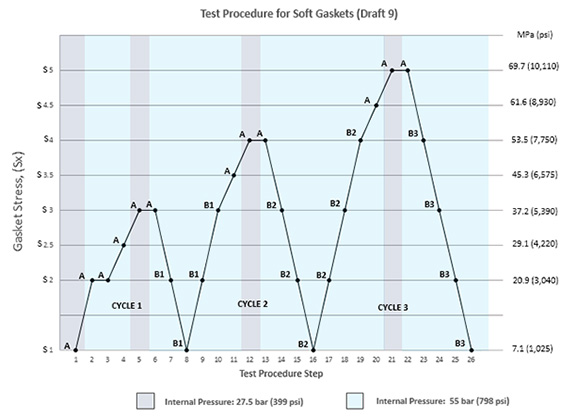

- A series of 3 loadings and unloading cycles is applied during which leak rate is measured at each stress level. Depending on the step, the system is pressurized to either 27.5 bar (399 psi) or 55 bar (798 psi) using helium gas. The holding time at each step is dependent on when a leak rate stabilizes, with a minimum hold time of 1 minute and a maximum hold time of 5 hours.

- The data collected is grouped into two Parts, Part A and Part B, and analyzed to generate the test parameters. Part A represents the initial seating performance of a gasket during initial flange tightening. Data from Part A is used to determine Gb, "a", and Tpmax. Part B simulates actual operating conditions. Data from Part B is used to determine Gs and Tpmin.

ROTT Test Procedure for Soft Gaskets

- The gasket stress is restored to S1 level.

- Loading cycles, with gradually increasing compression stresses, are applied on the gasket during which leak rate is measured at each stress level. The system is pressurized to 27.5 bar (399 psi) using helium gas. The holding time shall not exceed 15 minutes at each stress level.

- The test is complete when the leak rate at a stress level exceeds the leak rate observed at S1 level or when the maximum load of the equipment is reached.

- Maximum Allowable Stress is the maximum stress level where S1 leak rates were maintained.

ROTT Draft 9 SOFT Gasket Test Procedure

| Gasket Thickness: 1/16" | Gasket Thickness: 1/8" | |

|---|---|---|

| Gb (psi) | 685 | 770 |

| a | 0.271 | 0.274 |

| Gs (psi) | 6.19E-02 | 9.38E-07 |

| Tpmin | 1416 | 1962 |

| Tpmax | 27706 | 16424 |

| S100 (psi) | 2391 | 2716 |

| S1000 (psi) | 4466 | 5099 |

| S10000 (psi) | 8343 | 9573 |

| Maximum Allowable Gasket Stress (psi) | Greater than 40031 (Equipment Max) | Greater than 40031 (Equipment Max) |

ROTT Draft 9 SOFT Gasket Test Procedure

| Gasket Thickness: 1/16" | Gasket Thickness: 1/8" | |

|---|---|---|

| Gb (psi) | 441 | 155 |

| a | 0.3 | 0.411 |

| Gs (psi) | 8.55E-01 | 5.41E-02 |

| Tpmin | 2041 | 3210 |

| S100 (psi) | 45893 | 39160 |

| S1000 (psi) | 3495 | 2652 |

| S10000 (psi) | 6968 | 6839 |

| Maximum Allowable Gasket Stress (psi) | Greater than 40031 (Equipment Max) | 36260 |

Residents of some states have the right to opt-out of the “sharing” or “selling” of their personal information. Gore does not "sell" the personal information of website users. Gore may "share" the personal information of website users, as standard advertising practice meant to offer you a more personalized service.

If you want to opt-out from Gore “sharing” your personal information, click on Opt-Out of Sharing to turn off the targeting cookies that we share with our advertising partners in order to provide you with personalized information. Disabling sharing will stop the use of cookies to targeted advertising but you may still see generic Gore ads.

Please note that your exercising of the rights outlined will have no adverse effect on the price and quality of our goods or services.

Opt-Out of SharingYou Have Successfully Opted Out of the Sharing of Your Personal Information

Please note that if you clear your cookies and then use another device or browser, etc. your opt-out status is not transferred to the new device or browser.