A Small Change that Makes a Big Difference

New Challenges for Power Grids

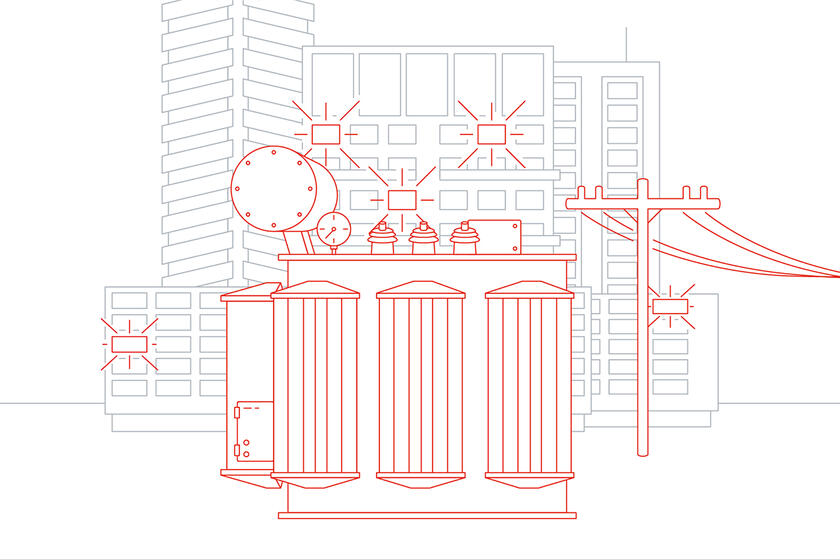

The energy infrastructure is changing in many ways, creating new challenges for all those involved in designing and maintaining power grids and their components. The complexity of power grid operations are significantly increased by a growing share of renewables, decentralization and interconnection of grid infrastructures, and new organizations such as energy communities.

MORE FLEXIBILITY IN THE GRID EQUALS INCREASED NEED FOR CONTROL AND MONITORING

Mastering this new level of complexity requires that both electricity transmission and distribution be managed more dynamically than ever before. Thus, existing equipment in the field and newly manufactured systems need to be assessed continually for internal system failures to ensure trouble-free operation and grid safety.

Luckily, most reasons for equipment failure are related to measurable conditions and can therefore be easily averted. This is where upgrading the monitoring and control devices in grid assets come into play.

RELIABILITY OF CONTROL AND MONITORING IS KEY FOR GRID SAFETY

Control and monitoring devices help to assess grid equipment conditions and detect issues, ideally before they become serious. Therefore, it is essential that these outdoor electronics work reliably. Otherwise, undetected problems could potentially lead to grid equipment failures or even worse - power grid failure. Manufacturers for control and monitoring components strive to achieve the highest levels of reliability in order to satisfy their customers. But how?

Protect Control and Monitoring Devices to Avoid Power Grid Failures

Grid control and monitoring devices include sensitive electronics surrounded by a sealed outdoor enclosure. If these outdoor electronics are not properly protected from environmental impacts, they can fail to detect and correct problems.

THESE ARE THE 5 BIGGEST PROBLEMS FOR OUTDOOR ELECTRONICS:

Moisture (risk for electrical shortage)

Salt (corrosion of PCB and components)

Vibration (cracks, mechanical issues - GORE® Polyvent Stainless Steel withstand IEC60068-2-64, so enclosure stays tight)

Dust (risk for electrical shortage)

Temperature (sealing stress related to temperature change)

Proper outdoor electronics protection* can prevent environmental damage to keep control and monitoring devices up and running – and with GORE Protective Vents it is very easy to implement.

GORE Protective Vents: Proper Protection for Grid Control and Monitoring Devices

Manufacturers of power grid equipment like transformers, switchgears, or reclosers can do their share to improve grid safety while using single components – especially those with sensitive electronics inside – with no compromise on protection against outdoor environments. GORE Protective Vents provide state-of-the-art outdoor protection for control and monitoring devices with the right IP (ingress protection) and IK (impact resistance) that is simple to integrate and usually doesn’t require design changes. Learn more about IP and IK in our data sheet:

It’s a small change that makes a big difference: By installing GORE Protective Vents, you keep the enclosure of sensitive electronics at the highest level of robustness and ingress protection to reliably protect outdoor electronics from moisture, dust, and salt.

A Simple Way to Improve Grid Safety and Satisfy Your Customers along the Grid Value Chain

Using GORE Protective Vents can prevent the escalation of a relatively small problem into a major one such as grid failure. When monitoring and control devices stay up and running because they are well-protected, they can reliably detect failure of crucial devices and enable grid operators to take appropriate measures before things lead to minor or even major grid failure.

Click through the slideshow and learn how control and monitoring component manufacturers contribute to overall grid safety by protecting their devices properly with GORE Protective Vents.

*GORE® Protective Vents for Energy Grid can reduce failures caused by temperature-induced pressure variations, moisture, dust condensation, and salt. There are further tertiary influences like lightning, mechanical factors, or sabotage which can lead into downtime of grid equipment.

GORE® Polyvent Stainless Steel: Exceptional Durability, Chemical and Corrosion Resistance

Customers today expect control and monitoring devices to come with a lifespan of 20 or more years, even in very harsh environments. GORE Polyvent Stainless Steel, a highly specialized GORE Protective Vent can help meet these expectations and maximize your product lifespan as they are exceptionally durable and corrosion resistant. The materials used in the vent make all the difference, providing reliable protection for enclosures even in harsh or changing environments. Plus, they reduce condensation.

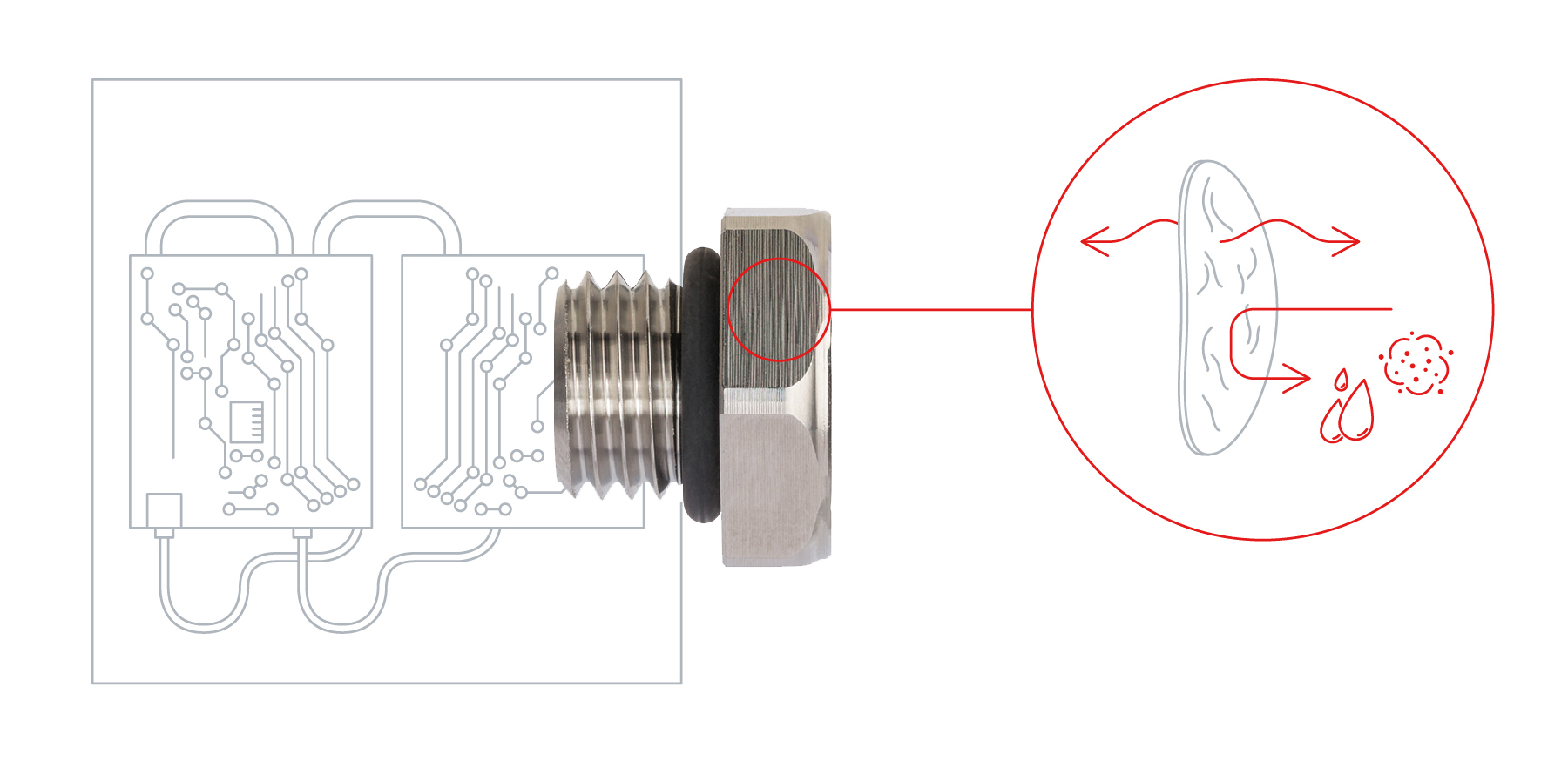

Materials Made for the Protection of Outdoor Electronics

Stainless Steel 1.4404: provides protection against high mechanical stresses (IK10; IEC 62262), chemicals, and corrosion thus meeting the specifications for grid equipment (IEC 62271-1).

GORE ePTFE Membrane: the vent provides a highly effective combination of breathability and barrier protection. To avoid any leakage related to adhesive failure, the membrane is fixed without adhesives and instead uses a patented spring for improved durability.

Silicone O-Ring: with excellent thermal resistance.

The GORE Polyvent Stainless Steel allows air and gases to pass through, equalizing differences in pressure between the enclosure and the outdoor environment with an IP protection of IP69K.

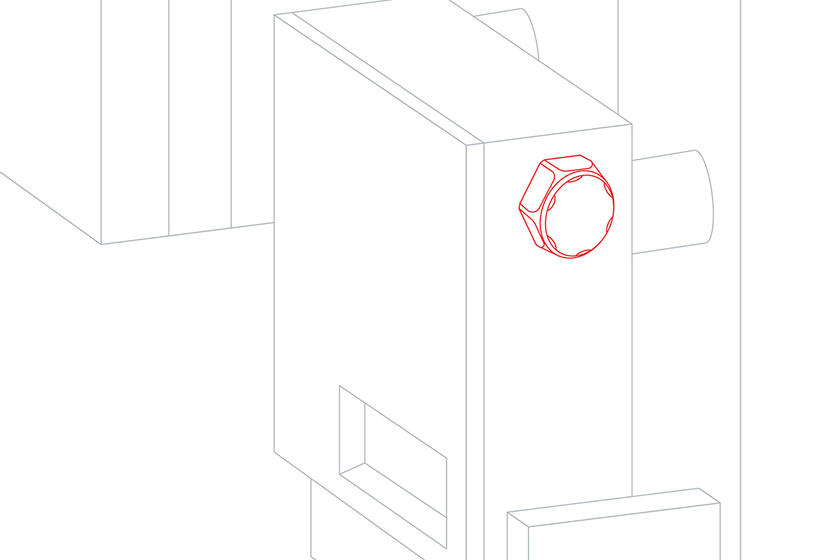

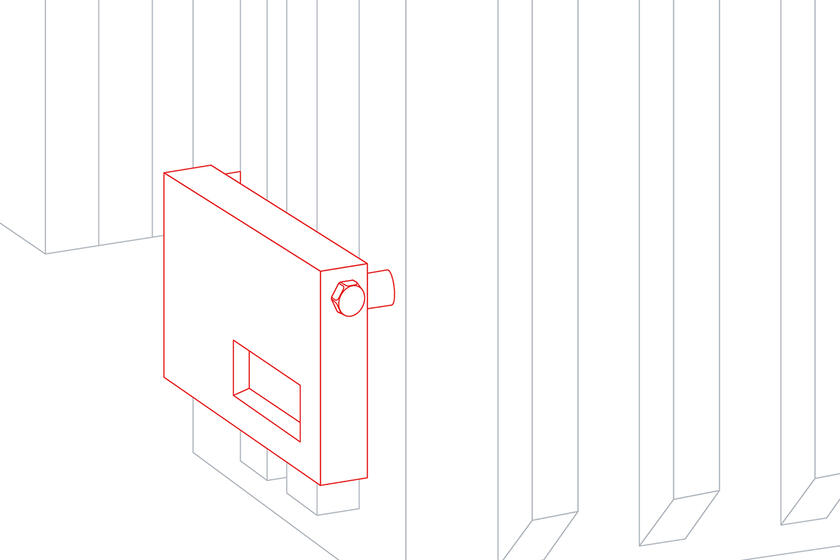

Your Control and Monitoring Device in Detail

GORE® Polyvent Screw in vent for easy integration with minimal design changes in housing

Silicone O-ring to provide optimal sealing performance with excellent thermal resistance

GORE® Polyvent Screw In vent for optimal protection against mechanical stresses (IK10) and corrosion

GORE ePTFE Membrane for reliable pressure equalization and barrier protection (IP69K)

A Wide Range of Applications for GORE Polyvent Stainless Steel

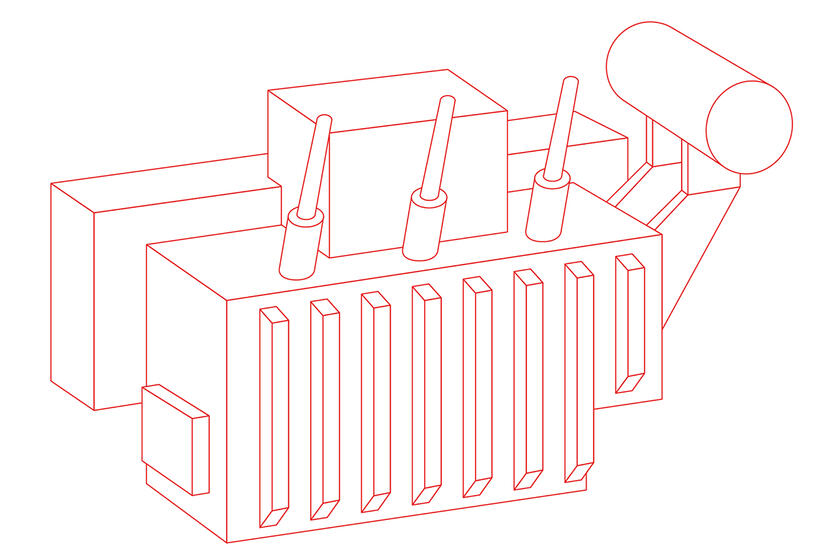

Whether your electronical control and monitoring devices are part of a high voltage substation set-up or a medium voltage installation, there are many control and monitoring devices in different types of grid equipment that can profit from the use of the right protective vent. GORE Protective Vents for Energy Grids can be used for the following:

| Transformer (HV / MV / LV) | Switch Gear | Recloser |

|---|---|---|

|

|

|

Dry Type Power Transformer

|

Air Insulated Substation (AIS)

|

Switching Units

|

Oil Transformers

|

Gas Insulated Substation (GIS)

|

It Pays to Compare: Extended Lifetime, Increased Profitability

GORE Protective Vents for energy grids are the latest technology to add to both your new and existing control and monitoring component designs. GORE Stainless Steel Vents outperform other types of vents, for example sintered or sponge vents, when it comes to product properties such as IP rating, robustness, or chemical resistance.

The superiority of GORE Protective Vents also reflects in their performance. Ingress protection, pressure equalization, plus the longevity and robustness of the materials used renders GORE Protective Vents a groundbreaking technology of great value to those seeking to make their grid control and monitoring devices work more reliably.

GORE Protective Vents vs. Common Venting Solutions

As the name says, GORE Protective Vents enable pressure equalization through venting with the key feature of ingress protection. Other venting technologies have limits to protecting against ingress of dust and moisture.

| GORE Polyvent Stainless Steel | Sintered Vent | Sponge Vent | Metal Mesh | Air Vent | |

|---|---|---|---|---|---|

|

|

|

|

|

|

| Moisture Ingress Protection* | ■■■ IP69K |

■ | ■ | ■ | ■ |

| Dust Ingress Protection* | ■■■ IP69K |

■■ | ■ | ■ | ■ |

| Pressure Equalization | ■■■ | ■■■ | ■■■ | ■■■ | ■■■ |

| Robustness | ■■■ IK10 |

■■ | ■ | ■ | ■ |

| Thermal Resistance | ■■■ | ■■■ | ■ | ■ | ■ |

| Corrosion Resistance** | ■■■ | ■ | ■ | ■ | ■ |

| Integration | ■■■ | ■■■ | ■ | ■ | ■ |

■■■ = high

■ = low

* Based on the following test scenario performed by GORE, simulating the change from a hot summer day to a sudden thunderstorm and subsequent condensation:

pretreatment 85C/85%RH storage 6hr -> ice water shower 10°C water spray 10min -> monitor condensation at room temperature with a heater inside (80°C)

** Based on salt spray test according to ASTM B117 for 120 hours.

For more detailed information on all of the comparison criteria, download our data sheet.

Want to Learn More?

Contact us to learn how a small change can make a big difference for you and how to increase the reliability and lifetime of your power grid control and monitoring devices.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.