GORE® Protective Vents for Heavy Duty Equipment

THERE ARE NO BAD CONDITIONS - Experience Reliability

Heavy-duty construction, material-handling and agricultural equipment relies on Gore vents to protect sensitive electronics from the harshest environments.

Contact Us

United States

+1 800 455 4684

Australia

+61 2 9473 6800

Benelux

+49 89 4612 2211

Brazil

+55 11 5502 7800

China

+86 21 5172 8299

France

+33 1 5695 6565

Germany

+49 89 4612 2211

India

+91 22 6768 7000

Israel

+972 3 649 0454

Italy

+39 045 6209 240

Japan

+81 3 6746 2572

Korea

+82 2 393 3411

Mexico

+52 81 8288 1281

Scandinavia

+46 31 706 7800

Singapore

+65 6733 2882

South Africa

+27 11 894 2248

South America

+55 11 5502 7800

Spain

+34 93 480 6900

Taiwan

+886 2 2173 7799

Turkey

+90 216 393 5749

United Kingdom

+44 1506 460123

Overview

Protect Your Electronics, Power Your Performance

Gore Protective Vents can extend the reliability and longevity of electronic enclosures for heavy-duty equipment in the most challenging applications.

Harsh environments demand robust solutions. Dirt, water, humidity, and extreme temperatures are constant challenges for heavy-duty equipment. As technology advances, with increased reliance on electronics and the rise of IIoT (Industrial Internet of Things), the need for reliable protection is paramount.

Traditional venting methods often fall short in these demanding conditions. Openings and tortuous paths may equalize pressure, but they also invite contaminants like dirt and water, leading to costly equipment failures. Condensation, a silent threat, can corrode sensitive electronics, resulting in downtime and increased maintenance costs.

Gore offers a superior solution. Our innovative vents provide a robust barrier against environmental threats while effectively equalizing pressure. By preventing condensation and contamination, we extend the life of your equipment, reduce downtime, and improve overall performance.

Our team of experts is dedicated to partnering with you to develop the perfect venting solution for your application. From design to installation, we provide comprehensive support to ensure your success.

Our vents master the challenges of Heavy-Duty equipment:

Increased Life Expectancy

Meet customers' expectation of outstanding durability and reliable operation for many years.

Holistic Design Approach

Eliminate the need for “ruggedized” housings, reducing costs and weight.

Space-saving Components

Provide a compact venting structure that is easily installed and integrated.

Improved Integration

Gore's expertise in prototyping, testing, and validation helps you adapt to the rapidly evolving automation technology.

Rapid Pressure Equalization

Rapidly equalize housing pressures to avert premature seal failure.

Superior Particle Protection

Prevent ingress from liquids, wind-driven rain or dust, and other particles.

Reducing Condensation

Enable the moisture to escape and prevent corrosion of sensitive electronics.

For more details on how these benefits support your application, please refer to our brochure.

Also, get in-depth information about how GORE Protective Vents offer reliable pressure equalization to protect enclsoures and seals provide protection from water hazards.

Applications

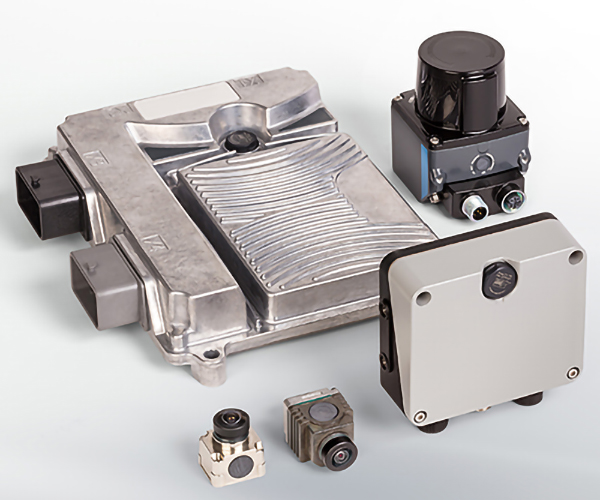

Gore Solutions: Vented Electronics Enclosures for Heavy-Duty Equipment

Construction Equipment

Gore vents reliably protect electronic systems in earth moving equipment, in road construction equipment, and in equipment for the mining industry.

Material-Handling Equipment

In cranes, forklifts and other warehouse equipment, GORE® Protective Vents can keep the electronic components operating at peak performance.

Agricultural Equipment

By increasing the life expectancy of outdoor electronics, Gore vents provide extended protection to investments in tractors, harvesting and cultivating machinery and forestry equipment.

Product Comparison

The portfolio of Gore’s industrial vents for heavy-duty equipment encompasses a wide range of performance characteristics to meet diverse application needs: from waterproof vent caps to vents that incorporate a reliable pressure-relief valve or high-flow air-vent valve.

The GORE® Protective Vent for Gearboxes has an integrated membrane that effectively blocks contaminants - like water, dust, and dirt - that can degrade the performance of oil cooled traditional and e-motors and other e-drivetrain components as well as gearboxes. The breathable GORE Membrane equalizes pressures under both normal and extreme operating conditions, to avert stress on seals.

Why Gore?

Heavy-duty machinery is made to last, and so are GORE Protective Vents. Our engineers are continuously evolving our membranes to offer you premium venting solutions for your sensitive electronics. The basis for all advances lies in test results and studies, such as Gore’s long-term field study: Since 2016, we have been exposing various models of GORE Protective Vents in all kinds of weather and using the data we gather to optimize the vents’ performance.

Optimizing Outdoor Electronics with GORE® Protective Vents

Optimizing Outdoor Electronics with GORE® Protective Vents

A recent field study confirms that GORE® Protective Vents are essential for maintaining the performance and durability of outdoor electronics. These vents ensure rapid pressure equalization, preventing seal damage caused by temperature fluctuations and protecting against water, dust, and other contaminants. An eight-year study in Putzbrunn, Germany, highlights their long-term effectiveness.

Learn more about these findings in our 2024 white paper.

IP / NEMA Rating

Find out which of our vents can help your enclosure deliver the desired protection level according to Ingress Protection (IP) or NEMA standards.

Comply with chemical regulations

The use of PFOA has been further restricted. Thanks to our expertise and infrastructure, we can help you meet the regulatory requirements. Rely on GORE® Vents for compliance, reliable supply and constant high performance and quality.

Resources

Brochure: GORE® Protective Vents for Heavy Duty Equipment

Brochures, 669.81 KB

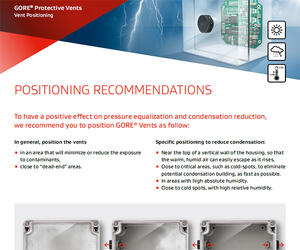

GORE® Protective Vents: Positioning Recommendations

Technical Information, 415.54 KB

View all resources for GORE Protective Vents for Heavy Duty Equipment

Recent News

Visit Booth 3070 to explore how GORE® Protective Vents are redefining durability and performance in extreme environments. Chat with our experts to learn how our venting solutions enhance reliability and extend the life of critical components in heavy-duty vehicles – no matter how tough the environment.

Event

Join Our Experts at the 42nd Annual International Battery Seminar in Orlando

March 17, 2025 - March 21, 2025

This year, Gore is proud to present two posters that address the evolving safety durability concerns in residential battery energy storage modules (BESS).

News

Safeguard Equipment and Your Investment: New GORE® Protective Vent for Gearboxes

Posted November 21, 2024

Safeguard Equipment and Your Investment: New GORE® Protective Vent for Gearboxes. A new venting solution to extend the life of oil-filled gearboxes, traditional and e-motors/drivetrains in heavy equipment, rail, marine and new energy applications.

In this FREE WEBINAR, you’ll learn about how to master moisture management in sealed enclosures & protect your battery and electronics.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.