GORE® Protective Vents for Telecommunication Systems

Housing vents from Gore reliably protect electronics against condensation and contaminants, for lower maintenance and warranty costs.

Contact Us

United States

+1 800 455 4684

Australia

+61 2 9473 6800

Benelux

+49 89 4612 2211

Brazil

+55 11 5502 7800

China

+86 21 5172 8299

France

+33 1 5695 6565

Germany

+49 89 4612 2211

India

+91 22 6768 7000

Israel

+972 3 649 0454

Italy

+39 045 6209 240

Japan

+81 3 6746 2572

Korea

+82 2 393 3411

Mexico

+52 81 8288 1281

Scandinavia

+46 31 706 7800

Singapore

+65 6733 2882

South Africa

+27 11 894 2248

South America

+55 11 5502 7800

Spain

+34 93 480 6900

Taiwan

+886 2 2173 7799

Turkey

+90 216 393 5749

United Kingdom

+44 1506 460123

Overview

More Reliable Connectivity with Reduced Manufacturing and Maintenance Costs

GORE Protective Vents reliably protect telecommunication enclosures in harsh or remote environments.

Today’s telecommunication systems aim for reliable connectivity everywhere — which can mean more equipment in remote locations, with enclosures and cabinets that are exposed to extreme environmental conditions.

GORE Protective Vents can extend the service life of outdoor telecommunication equipment, reducing maintenance costs, warranty claims and customer frustrations, because they:

- effectively manage pressure differentials within the equipment housing

- prevent condensation from compromising sensitive electronics

- reduce stress on housing seals

- block ingress of rain, moisture, wind-borne particulates and other contaminants

- eliminate the need for “ruggedized” housings, reducing costs and weight

Gore, the global leader in venting technology, has more than 15 years’ experience in developing custom venting solutions for the telecommunications industry. Our global R&D and engineering teams can partner with you from initial product concept through prototyping, sampling, testing and production integration.

GORE® Protective Vents can help your communications enclosure or cabinet meet IP and NEMA protection standards. Learn more.

Why Vent?

Electronic communications enclosures that are installed outdoors are vulnerable to a wide range of environmental hazards that can affect the performance, reliability and life expectancy of the sensitive electronics within.

These hazards — such as extreme temperatures, driving rain or high humidity, or wind-, ice- or dust-storms — can threaten the integrity of standard or custom telecommunications enclosures by repeatedly stressing and weakening their seals or gaskets.

Problems for Outdoor Electronics:

RELIABLE TELECOM ENCLOSURE SOLUTIONS WITH GORE PROTECTIVE VENTS:

Applications

Venting Solutions for Different Telecommunication Applications

| Tower-Top Electronic Enclosures | |

| Water can cause corrosion and shorts to the electronics in tower-top enclosures. By allowing moisture vapor to diffuse easily, GORE Protective Vents reduce potential condensation that leads to corrosion and shorts. | |

| Base Station Battery Units | |

| To prevent potential explosions, hydrogen gases from batteries must have an exit path. The continuous airflow of GORE Protective Vents enables gases to flow out of the unit while creating a barrier against contaminants. | |

| Small Cell Nodes | |

| Plastic housings commonly used in small cell nodes are more susceptible to pressure equalization issues. Gore’s venting solutions protect the electronics from water damage and comply with environmental standards. | |

| Antenna Tilt Motors | |

| Mechanical components of the antenna motors can fail when exposed to liquids and other contaminants. GORE Protective Vents provide a barrier against liquid and other contaminants that can lead to corrosion. | |

| Coverage Systems | |

| Water ingress can compromise the signal integrity of coverage devices like repeaters and backhaul devices, including point-to-point and microwave radios. By equalizing pressure inside the device housing, GORE Protective Vents prevent stress on the housing seals so water cannot enter. | |

| Tower-Mounted Sensors | |

| Rapid temperature changes create a vacuum inside the sensor, which can cause a seal to fail. Moisture vapor can enter and condense on the sensor dome, obstructing sunlight and compromising sensor measurements. GORE Protective Vents equalize pressure and prevent vacuums that compromise seal integrity. | |

Product Comparison

IP / NEMA Rating

Find out which of our vents can help your enclosure deliver the desired protection level according to Ingress Protection (IP) or NEMA Standards.

Resources

GORE® Protective Vents - Telecommunication Systems

Brochures, 1.09 MB

Reliability Testing of GORE® Protective Vents in Telecommunication Enclosures

White Papers, 659.05 KB,

GORE® Protective Vents Reduce Condensation in Sealed Enclosures

Case Studies, 292.36 KB

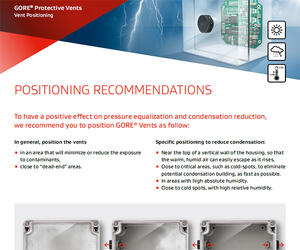

GORE® Protective Vents: Positioning Recommendations

Technical Information, 415.54 KB

View all resources for GORE Protective Vents for Telecommunication Systems

Recent News

Event

Join Our Experts at the 42nd Annual International Battery Seminar in Orlando

March 17, 2025 - March 21, 2025

This year, Gore is proud to present two posters that address the evolving safety durability concerns in residential battery energy storage modules (BESS).

News

Safeguard Equipment and Your Investment: New GORE® Protective Vent for Gearboxes

Posted November 21, 2024

Safeguard Equipment and Your Investment: New GORE® Protective Vent for Gearboxes. A new venting solution to extend the life of oil-filled gearboxes, traditional and e-motors/drivetrains in heavy equipment, rail, marine and new energy applications.

In this FREE WEBINAR, you’ll learn about how to master moisture management in sealed enclosures & protect your battery and electronics.

Event

Discover the world of Gore at IEEE SENSORS 2024 in Kobe, Japan!

October 21, 2024 - October 23, 2024

Join us at IEEE SENSORS 2024 , a renowned event in the field of sensor technology and innovation. We are excited to announce that W. L. GORE & Associates G.K. will be unveiling cutting edge solutions at booth #6 during the conference, from October 21st to October 23rd.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.