| Thickness | ||

|---|---|---|

| 6 mm (1/4") | 9 mm (3/8") | |

| PQR, 150° C (302° F) | 0.49 | 0.41 |

| PQR, 230 °C (445 °F) | 0.36 | 0.29 |

Based on EN 13555 creep relaxation test protocol (PQR).

2 x 250mm x 55mm strips, 500 kN/mm, 10 MPa starting stress.

| Thickness | ||

|---|---|---|

| 6 mm (1/4") | 9 mm (3/8") | |

| Qmin (0.1) | 9 MPa (1,305 psi) |

13 MPa (1,885 psi) |

| Qmin (0.01) | 14 MPa (2,030 psi) |

18 MPa (2,610 psi) |

| Qsmin up to L0.0001 and QA > 5 MPa | 5 MPa (725 psi) |

5 MPa (725 psi) |

| m | 5 | 5 |

| y | 9 MPa (1,305 psi) |

13 MPa (1,885 psi) |

Based on EN 13555 leakage test protocol. DN200 PN10 plattens, 10 bar nitrogen, 30 mm wide tape.

| Thickness | ||

|---|---|---|

| 6 mm (1/4") | 9 mm (3/8") | |

| Stress to seal 0.1 mg/(m•s) measured on test plattens with a groove |

9 MPa (1,300 psi) |

13 MPa (1,885 psi) |

| Stress to seal 0.01 mg/(m•s) measured on test plattens with a groove |

14 MPa (2,030 psi) |

18 MPa (2,610 psi) |

Based on EN 13555 leakage test protocol. DN200 PN10 plattens, with 0.5mm deep groove with sloped edges cut into the plattens, 10 bar nitrogen, 30 mm wide tape.

| Thickness | ||

|---|---|---|

| 6 mm (1/4") | 9 mm (3/8") | |

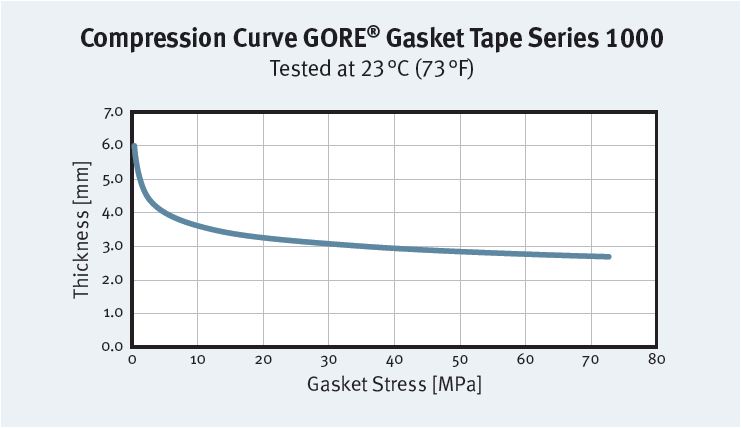

| Max. surface stress at 23° C (73° F) | 70 MPa (10,150 psi) |

70 MPa (10,150 psi) |

2 x 250 mm x 55 mm strips, 500 kN/mm, 0.1 MPa/s load rate, 15 min hold time, no visible damage.