Technical Information

GORE® Membrane Technology vs. Non-Membrane Media: Industrial Baghouse Filters

Learn the differences between membrane and non-membrane filter media. GORE Membrane Technology provides longer bag life, lower emissions rates, lower pressure drops and has better throughput.

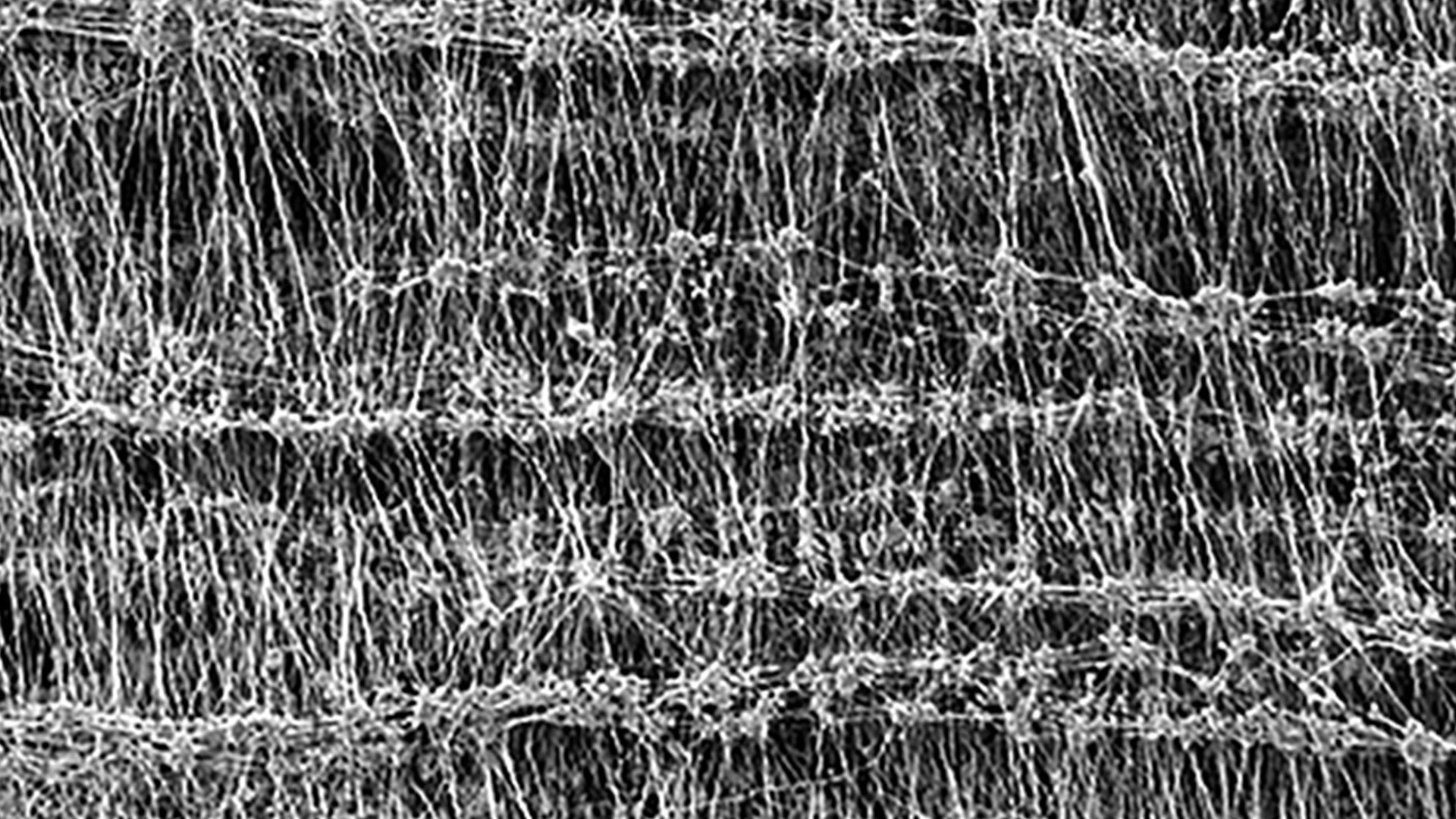

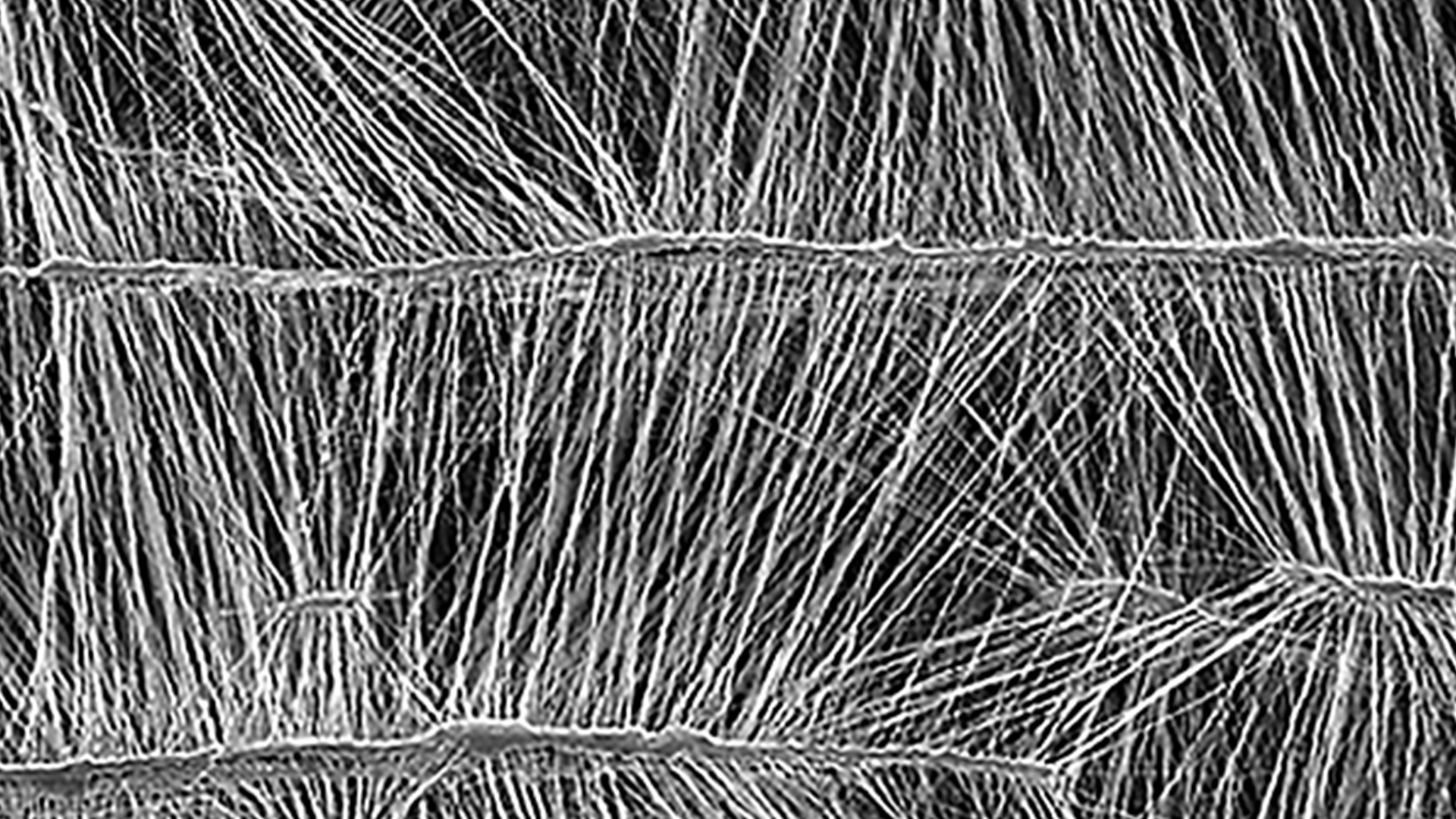

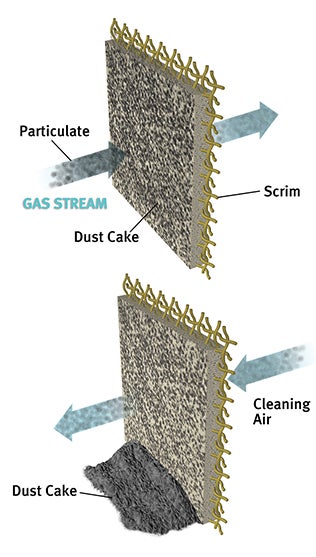

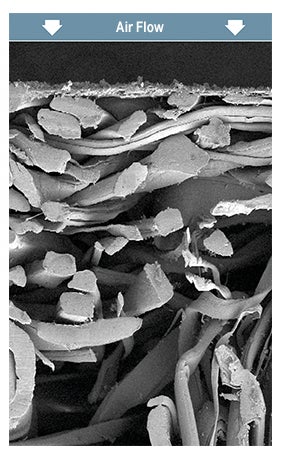

Non-Membrane Depth Filtration

Filtering Mode

- Dust is filtered inside of filter media

- Internal dust cake buildup required

- Particles enter into filter media and can pass through

- Might not filter finest particles

- Efficiency requires careful balance between filter, particulate, and system conditions

Cleaning Mode

- Difficult to remove particles, only surface dust cake is removed

- Dust deep inside media can cause higher Dp and blinding with time

- Dust buildup inside media can lead to emissions after cleaning

Image

Image

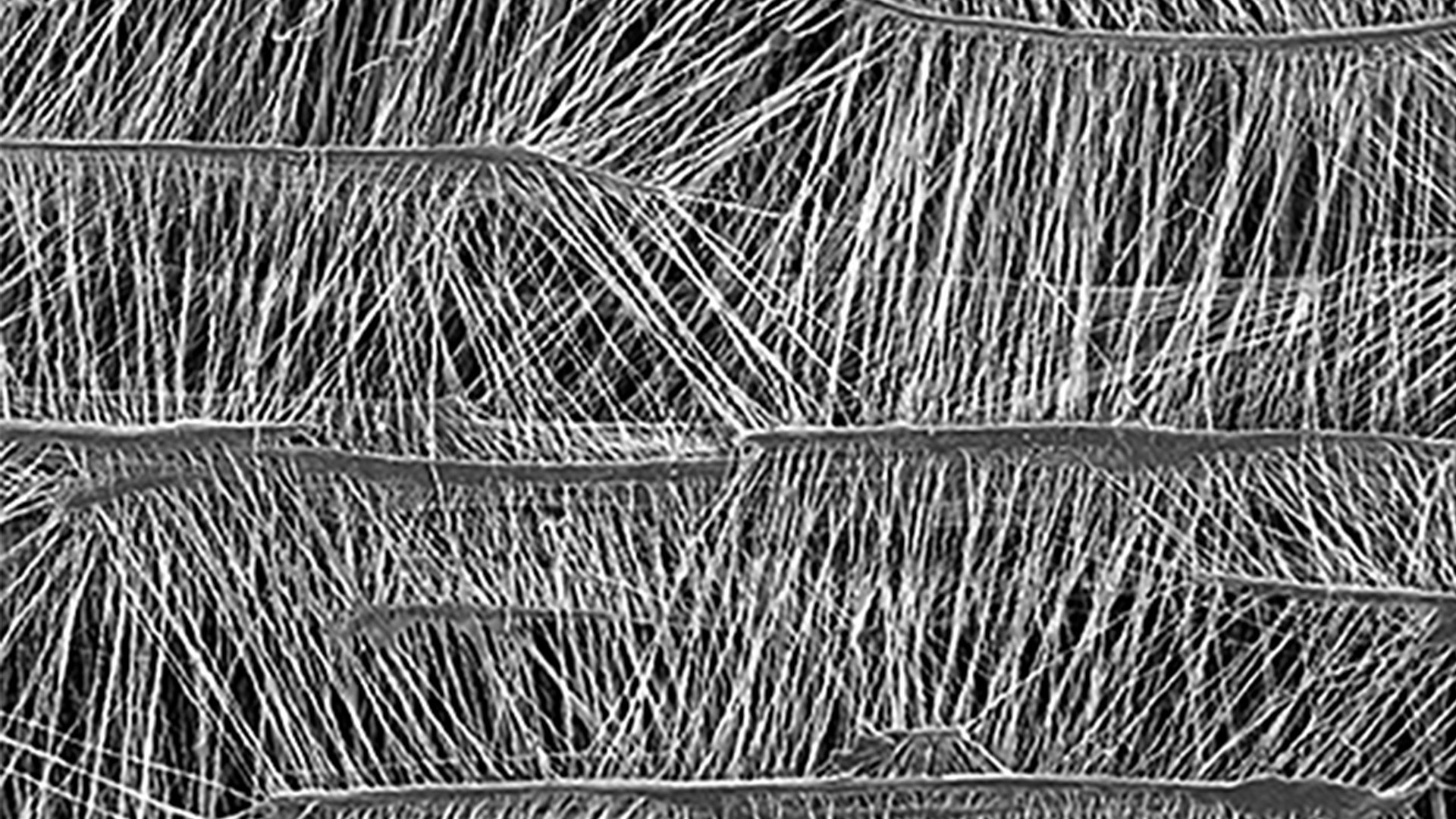

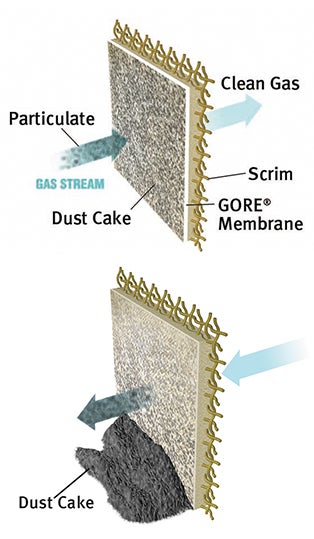

Membrane Surface Filtration

Filtering Mode

- Dust filtered at membrane surface

- No dust cake buildup required

- No particles enter backer

- Capable of submicron filtration

- Maintains capture efficiency over wide range of system conditions

Cleaning Mode

- Almost all dust falls off membrane surface

- Particles do not build up inside backer

- Surface is hydrophobic, even wet dust cakes can still be handled

Image

Image

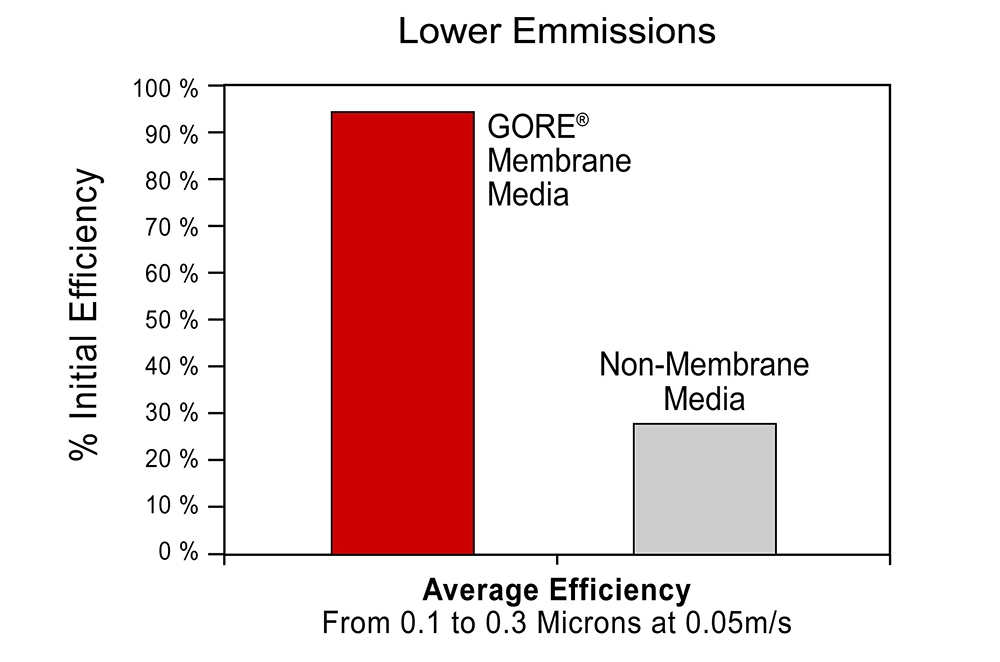

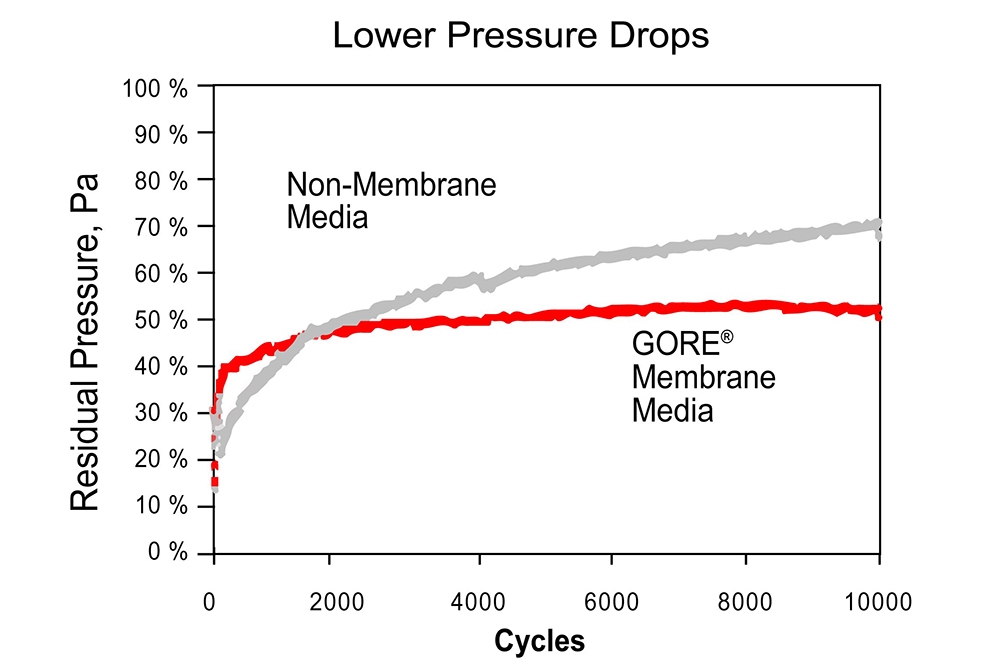

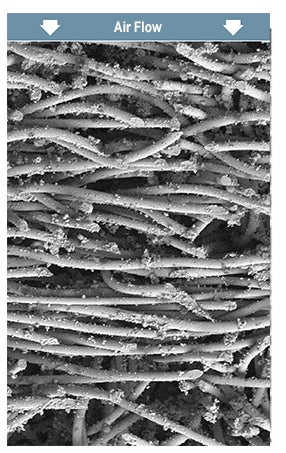

GORE Membrane Efficiency and Versatility

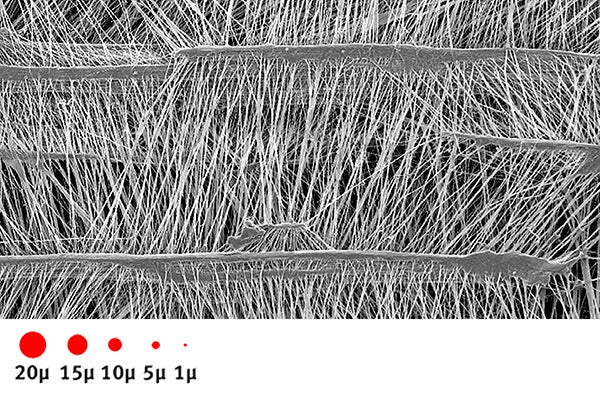

Membrane (500x)

Image

Surface Filtration

Uniform membrane structure allows higher efficiency.

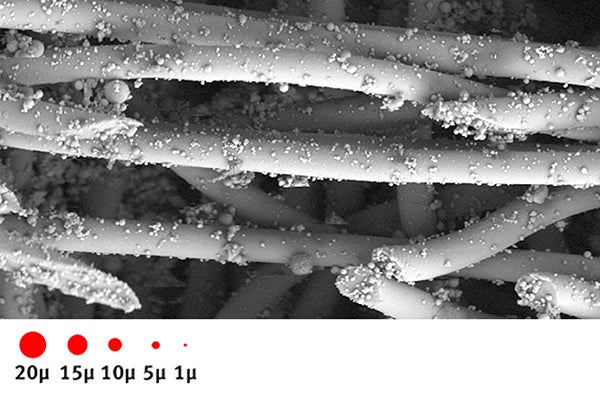

Non-Membrane (500x)

Image

Depth Filtration

Dust still penetrates into backer and is trapped.

Gore has developed a family of membranes for use in industrial filtration applications

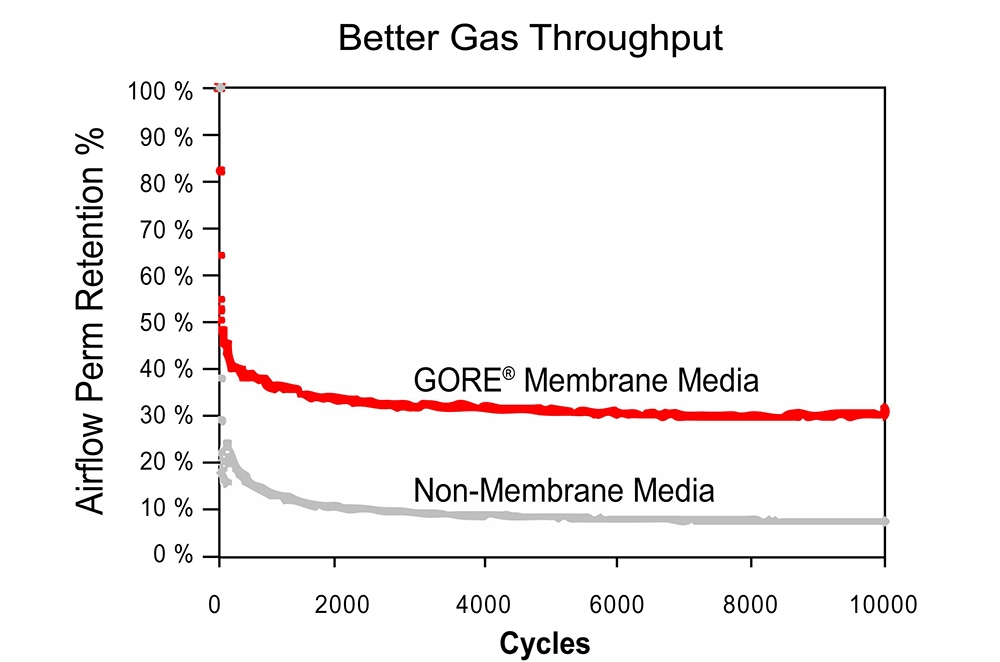

GORE Membrane Performance Charts

GORE Membrane Filters are not just cleanable, they are also more efficient and last longer.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.